Izixhumi zesilisa zesilisa ze-PCB ezisezingeni eliphezulu

Okomzimba

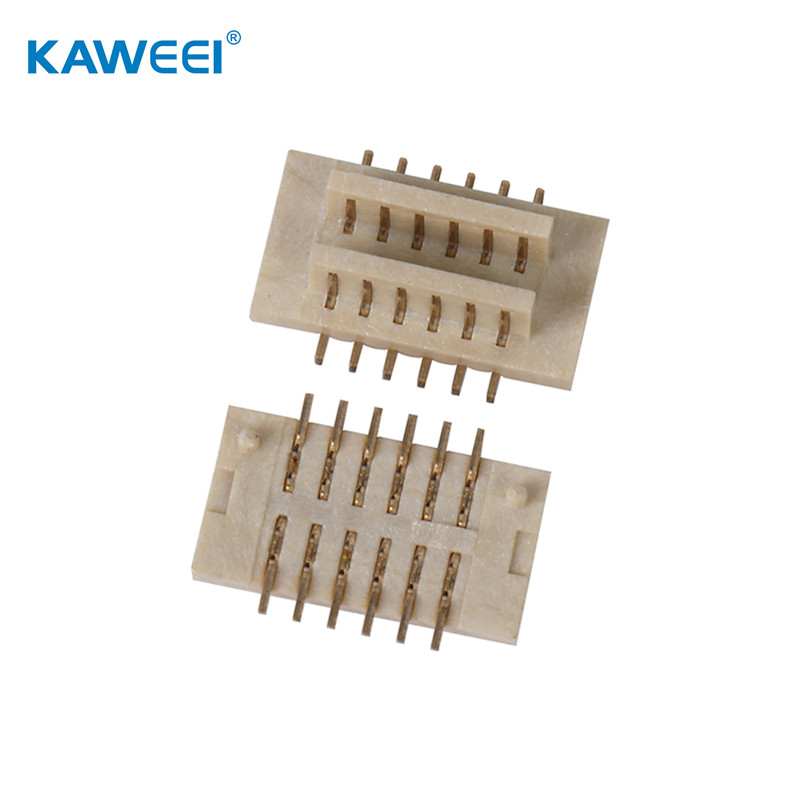

| Igama Lomkhiqizo | Ibhodi elijwayelekile ukuya ebhodini lekhwalithi ye-PCB Board Isixhumi |

| Umbala - Resin | Njengesithombe |

| Plating - Terminal | Igolide Flash |

| Material - Plating Ukukhwelana | Igolide licwebezela phezu kweNickel |

| Material - Izindlu | Inayiloni 6T, UL94V-0 |

| Ibanga Lokushisa Lokusebenza | -40°C kuya +105°C |

Ezogesi

| Okwamanje - Ubuningi | 0.5 Amp |

| I-Voltage - Isilinganiso esiphezulu | 150V AC/DC |

| Ukumelana nokuxhumana: | 50m Ohm Max |

| Ukumelana ne-insulator: | 500MΩMin |

| Ukumelana ne-Voltage: | 200V AC/Iminithi |

Omaka bomkhiqizo

● Isixhumi se-FPC

● Wngibheke Isixhumi Sebhodi

● Bukuya kusixhumi seBhodi

● PIsixhumi sebhodi le-CB

● PIsixhumi se-CB

● FIsixhumi se-FC

● ZIsixhumi se-IP

● Sisixhumi esikhulile

● I-FPCSIsixhumi se-MT

● FIsixhumi esiqondile se-FC

Imibuzo nezimpendulo ezivame ukubuzwa

Umbuzo: ingabe isixhumi sebhodi ukuya ebhodini nesixhumi somugqa kuya ebhodini siwuhlobo olufanayo lomkhiqizo wokuxhuma?

A: Isixhumi sebhodi ukuya ebhodini nesixhumi somugqa kuya ebhodini, isixhumi somugqa kuya kumugqa asilona uhlobo olufanayo lomkhiqizo wokuxhuma.

Q: Ungakhetha kanjani isixhumi sebhodi ukuya ebhodini?

A: Isixhumi sepuleti-kuya-plate siyingxenye ye-electromechanical exhuma amasekhethi kagesi. Imingcele kagesi yiyona yokuqala yokucatshangelwa. Izici zemishini zezixhumi zifaka ukudlidliza, umthelela, ukusheshisa, impilo yemishini, ipulaki namandla okudonsa, njll.

Q: ukuthi izixhumi zepuleti kuya kuplate zinganciphisa kanjani ukugqoka kukaJack namaphini.

A: ukukhulisa amandla okucwecwa kwegolide endaweni yokuxhumana yezixhumi zeplate-to-plate kunganciphisa ngempumelelo ukungqubuzana.

Q: Kufanele sigcinwe kanjani isixhumi sebhodi ebhodini?

A: Izinto zokufakelwa kwezixhumi zezintambo zikagesi kufanele zigcinwe endaweni yokugcina impahla ehlanzekile, epholile, eyomile futhi enomoya. Isikhathi sokugcina siyizinyanga eziyi-12 kusukela ngosuku lokukhiqiza

Q: Yiziphi izakhiwo eziyisisekelo zezixhumi zepuleti-kuya-puleti?

A: izakhiwo eziyisisekelo zezixhumi ze-plate-plate zingahlukaniswa ngezigaba ezintathu: izakhiwo zemishini, izakhiwo zikagesi kanye nezindawo zemvelo.

1.Ukuqinisekisa ukuthembeka kwezinto ezingavuthiwe

Kunelabhorethri yayo ekhethekile yezinto ezingavuthiwe ezikhethiwe zokuqinisekisa ukusebenza nokuqapha izinga, ukuze kuqinisekiswe ukuthi impahla ngayinye kulayini ifanelekile;

2. Ukuthembeka kokukhethwa kwetheminali / isixhumi

Ngemva kokuhlaziya imodi yokwehluleka okuyinhloko kanye nefomu lokwehluleka kwamatheminali nesixhumi, amadivaysi ahlukene anezindawo ezihlukene zokusetshenziswa akhetha izinhlobo ezahlukene zezixhumi ukuze azivumelanise nazo;

3. Ukwethenjwa komklamo wesistimu kagesi.

Ngokwesimo sokusetshenziswa komkhiqizo ngokuthuthukiswa okunengqondo, ukuhlanganisa imigqa kanye nezingxenye, ezihlukaniswe ngokucubungula kwe-modular, ukunciphisa umjikelezo, ukuthuthukisa ukuthembeka kwesistimu kagesi;

4. Ukwethenjwa kwedizayini yenqubo yokucubungula.

Ngokwesakhiwo somkhiqizo, sebenzisa izimo, izidingo zezimpawu zokuklama inqubo yokucubungula engcono kakhulu, ngokusebenzisa isikhunta kanye namathuluzi ukuze uqinisekise ubukhulu bokhiye bomkhiqizo kanye nezidingo ezihlobene.

Umkhiqizi wamahhanisi wezintambo weminyaka eyi-10

✥ Ikhwalithi Enhle Kakhulu: Sinesistimu yokulawula ikhwalithi eqinile kanye nethimba lekhwalithi yochwepheshe.

✥ Isevisi eyenziwe ngokwezifiso: Yamukela ukuhlanganisa okuncane kwe-QTY & Ukusekela komkhiqizo.

✥ Isevisi yangemuva kokuthengisa: Uhlelo olunamandla lwesevisi yangemva kokuthengisa, oluku-inthanethi unyaka wonke, luphendula kahle uchungechunge lwemibuzo yokuthengisa kwamakhasimende ngemva kokuthengisa

✥ Isiqinisekiso Sethimba : Ithimba eliqinile lokukhiqiza, ithimba le-R & D, ithimba lokumaketha, isiqinisekiso samandla.

✥ Ukulethwa Okusheshayo: Isikhathi sokukhiqiza esivumelana nezimo sisiza kuma-oda akho aphuthumayo.

✥ Intengo yefekthri: Yiba ngumnikazi wefekthri, ithimba labaklami lochwepheshe, linikeza intengo engcono kakhulu

✥ Isevisi yamahora angu-24: Ithimba labadayisi abaqeqeshiwe, elihlinzeka ngezimpendulo eziphuthumayo zamahora angu-24.