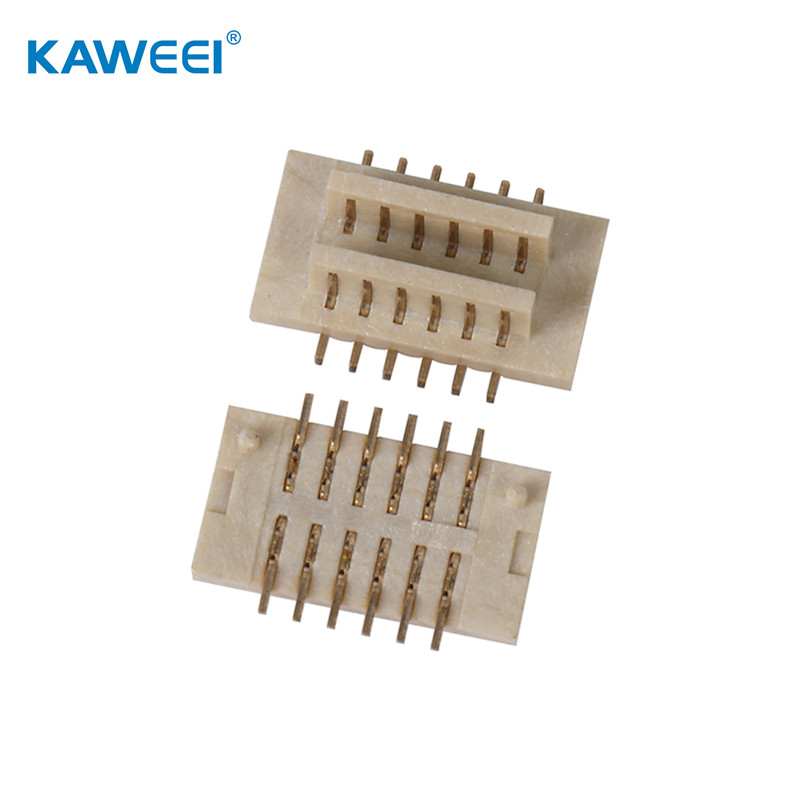

Umgangatho ophezulu PCB solder indoda izihlanganisi female

Ngokwasemzimbeni

| Igama lemveliso | Ibhodi esemgangathweni kwibhodi yebhodi yebhodi yePCB isiqhagamshelo |

| Umbala - Resin | Njengomfanekiso |

| Ukucwenga - Itheminali | Gold Flash |

| Material - Plating Mating | Igolide yalekwe phezu kweNikeli |

| Izinto eziphathekayo - Izindlu | Inayiloni 6T, UL94V-0 |

| Uluhlu lobushushu bokusebenza | -40°C ukuya +105°C |

Umbane

| Okwangoku - Ubuninzi | 0.5 Amp |

| Voltage - Ubuninzi | I-150V AC / DC |

| Ukuchasa ukunxibelelana: | 50m Ohm Max |

| Ukuxhathisa kwi-insulator: | 500MΩMin |

| Ukumelana nombane: | 200V AC/Umzuzu |

Iithegi zeMveliso

● Isidibanisi seFPC

● WkuMdibaniso weBhodi

● Bukuya kwisinxibelelanisi seBhodi

● PIsidibanisi sebhodi yeCB

● PIsidibanisi se-CB

● FIsidibanisi seFC

● ZIP Isidibanisi

● Sisinxibelelanisi esindala

● I-FPCSIsidibanisi seMT

● FIsidibanisi esithe nkqo seFC

Imibuzo neempendulo ezidla ngokubuzwa

Umbuzo: Ngaba ibhodi-ibhodi-ibhodi edibanisayo kunye nomgca-kwibhodi yokudibanisa uhlobo olufanayo lwemveliso yokudibanisa?

A: Isidibanisi sebhodi ukuya kwibhodi kunye ne-line-to-board connector, i-line-to-line connector ayilona uhlobo olufanayo lwemveliso yokudibanisa.

Q: Indlela yokukhetha ibhodi-to-ibhodi isinxibelelanisi?

A: Isidibaniso seplate-to-plate siyinxalenye ye-electromechanical edibanisa iisekethe zombane. Iiparamitha zombane ziqwalaselo lokuqala. Iipropati ze-Mechanical of connectors zibandakanya ukungcangcazela, impembelelo, ukukhawuleza, ubomi bomatshini, iplagi kunye namandla okutsala, njl.

Umbuzo: indlela ipleyiti-to-plate izihlanganisi inokunciphisa Jack kunye pin ukunxiba.

A: Ukwandisa amandla eplating yegolide kumphezulu woqhagamshelwano weplate-to-plate izihlanganisi kunokunciphisa ngempumelelo ukukhuhlana.

Q: Kufuneka igcinwe njani ibhodi kwibhodi isinxibelelanisi?

Mp Ixesha lokugcinwa ziinyanga ezili-12 ukusuka kumhla wemveliso

Umbuzo: Ziziphi iimpawu ezisisiseko zeplate-to-plate izixhumi?

A: iipropathi ezisisiseko zeplate-to-plate connectors zingahlulwa zibe ngamacandelo amathathu: iipropathi zomatshini, iipropati zombane kunye neendawo zokusingqongileyo.

1.Ukuqinisekisa ukuthembeka kwemathiriyeli ekrwada

Kukho ilabhoratri yayo ekhethekileyo yezixhobo ezikhethiweyo zokuqinisekisa ukusebenza kunye nokubeka iliso lomgangatho, ukuqinisekisa ukuba yonke into ekumgca ifanelekile;

2. Ukuthembeka kwe-terminal / ukhetho lokudibanisa

Emva kokuhlalutya imowudi yokungaphumeleli ephambili kunye nefomu yokungaphumeleli kwee-terminals kunye nekhonkco, izixhobo ezahlukeneyo ezineendawo ezahlukeneyo zokusetyenziswa zikhetha iindidi ezahlukeneyo zokuxhuma ukulungelelanisa;

3. Ukuthembeka koyilo lwenkqubo yombane.

Ngokwemeko yokusetyenziswa kwemveliso ngokuphuculwa okufanelekileyo, ukudibanisa imigca kunye namacandelo, ahluke kwi-modular processing, ukunciphisa isiphaluka, ukuphucula ukuthembeka kwenkqubo yombane;

4. Ukuthembeka koyilo lwenkqubo yokucubungula.

Ngokwesakhiwo semveliso, sebenzisa iimeko, iimfuno zeempawu zokuyila eyona nkqubo yokucubungula, ngokubumba kunye nezixhobo zokuqinisekisa imilinganiselo engundoqo yemveliso kunye neemfuno ezinxulumene nazo.

Iminyaka eyi-10 yomenzi wokubopha iintambo zobungcali

✥ Umgangatho ogqwesileyo: Sinenkqubo engqongqo yolawulo lomgangatho kunye neqela elisemgangathweni.

✥ Inkonzo elungiselelweyo: Yamkela i-QTY encinci kunye nenkxaso yokudibanisa imveliso.

✥ Inkonzo yasemva kokuthengisa: Inkqubo yenkonzo yasemva kokuthengisa enamandla, kwi-intanethi unyaka wonke, iphendula ngokugqibeleleyo uthotho lwemibuzo yokuthengisa emva kokuthengisa.

✥ Isiqinisekiso seQela : Iqela lemveliso elomeleleyo, iqela le-R & D, iqela lezentengiso, isiqinisekiso samandla.

✥ Ukuhanjiswa ngokukhawuleza: Ixesha lemveliso eliguquguqukayo liyanceda kwii-odolo zakho ezingxamisekileyo.

✥ Ixabiso lasefektri: Ngumnikazi wefektri, iqela loyilo lobuchwephesha, libonelela ngexabiso elifanelekileyo

✥ Inkonzo yeeyure ezingama-24: Iqela lokuthengisa leengcali, elibonelela ngempendulo engxamisekileyo yeeyure ezingama-24.