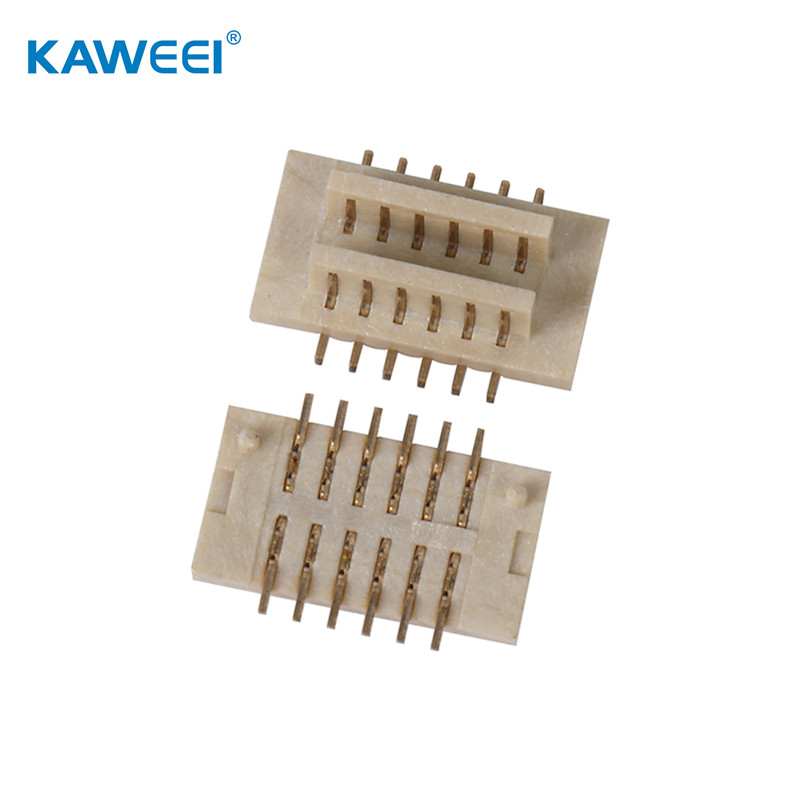

High quality PCB solder male female connectors

Physical

| Product Name | Standard board to board quality PCB Board Connector |

| Color - Resin | As picture |

| Plating - Terminal | Gold Flash |

| Material - Plating Mating | Gold plating over Nickel |

| Material - Housing | Nylon 6T, UL94V-0 |

| Working Temperature Range | -40°C to +105°C |

Electrical

| Current - Maximum | 0.5 Amp |

| Voltage - Maximum | 150V AC/DC |

| Contact resistance: | 50m Ohm Max |

| Insulator resistance: | 500MΩMin |

| Withstanding Voltage: | 200V AC/Minute |

Product Tags

● FPC Connector

● Wire to Board Connector

● Board to Board connector

● PCB board connector

● PCB connector

● FFC connector

● ZIP Connector

● Soldering connector

● FPC SMT Connector

● FFC Vertical connector

Frequently asked questions and answers

Q: is the board-to-board connector and line-to-board connector the same type of connector product?

A: A board-to-board connector and line-to-board connector, line-to-line connector is not the same type of connector product.

Q: How to choose the board-to-board connector?

A: A plate-to-plate connector is an electromechanical component that connects electrical circuits. Electrical parameters are the first consideration. Mechanical properties of connectors include vibration, impact, acceleration, mechanical life, plug and pull force, etc. .

Q: how plate-to-plate connectors can reduce Jack and pin wear.

A: increasing the strength of the gold plating on the contact surface of the plate-to-plate connectors can effectively reduce friction.

Q: How should the board to board connector be stored?

A: the insulation materials for electronic wire connectors should be stored in a clean, cool, dry and ventilated warehouse. The storage period is 12 months from the production date

Q: What are the basic properties of plate-to-plate connectors?

A: the basic properties of plate-to-plate connectors can be divided into three categories: mechanical properties, electrical properties and environmental properties.

1.Verification reliability of raw materials

There is its own special laboratory for the selected raw materials for performance verification and quality monitoring, to ensure that each material on the line is qualified;

2. Reliability of the terminal / connector selection

After analyzing the main failure mode and failure form of terminals and connector, different devices with different use environments choose different types of connectors to adapt;

3. Design reliability of the electrical system.

According to the product use scenario through reasonable improvement, merge lines and components, differentiated to modular processing, to reduce the circuit, improve the reliability of the electrical system;

4. Design reliability of the processing process.

According to the product structure, use scenarios, characteristics requirements to design the best processing process, through the mold and tooling to ensure the product key dimensions and related requirements.

10 years professional wiring harness manufacturer

✥ Excellent Quality: We have strict quality control system and professional quality team.

✥ Customized Service: Accept small QTY & Support product assembling.

✥ After-sales service: Powerful after-sales service system, online throughout the year, perfectly answering series of after-sales customer sales questions

✥ Team Guarantee : Strong production team, R & D team, marketing team, strength guarantee.

✥ Prompt Delivery: Flexible production time helps on your urgent orders.

✥ Factory price: Own the factory, the professional design team, provides the best price

✥ 24 Hour service: Professional sales team, providing 24-hour emergency response.