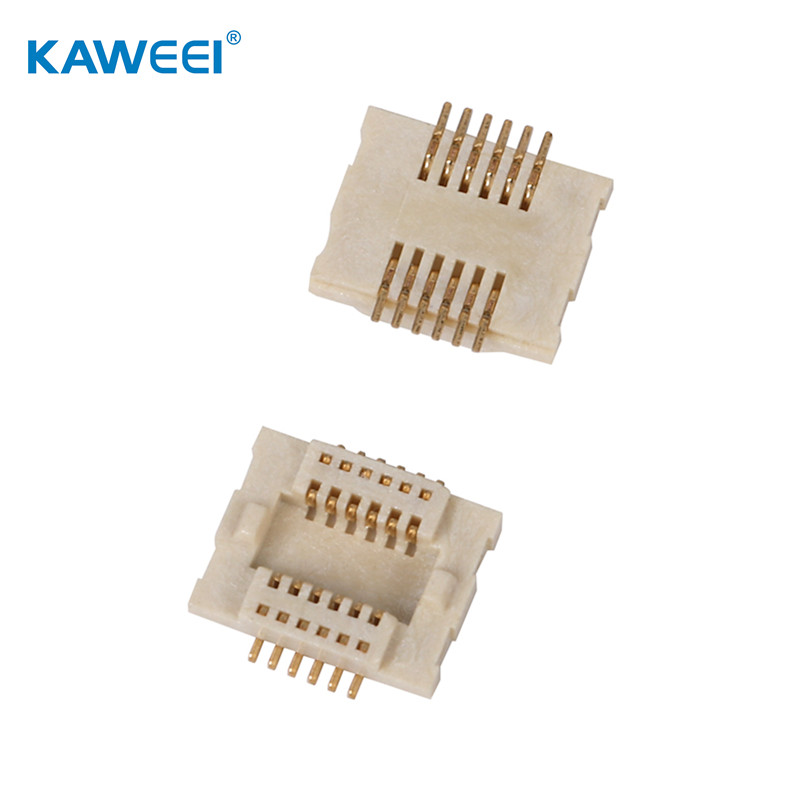

Board to Board Printed circuit board connector

Physical

| Product Name | Standard board to board quality PCB Board Connector |

| Color - Resin | As picture |

| Plating - Terminal | Gold Flash |

| Material - Plating Mating | Gold plating over Nickel |

| Material - Housing | LCP UL94V-0 |

| Temperature Range - Operating | -25°C to +105°C |

Electrical

| Current - Maximum | 0.5 Amp |

| Voltage - Maximum | 50V AC/DC |

| Contact resistance: | 40m Ohm Max |

| Insulator resistance: | 800M ohm min. |

| Withstanding Voltage: | 200V AC/Minute |

Product Tags

● FPC Connector

● Wire to Board Connector

● Board to Board connector

● PCB board connector

● PCB connector

● FFC connector

● ZIP Connector

● Soldering connector

● FPC SMT Connector

● FFC Vertical connector

FAQ

Q1: Can I get some samples?

Yes, sample order is available, some samples are free, and it will be freight collect payment.

Q2: How long is your lead time?

Normally, our wire harness lead time is 2~4wks, connector lead time is 7-10days according to different products.

Q3: What’s your payment term?

We accept T/T and Paypal.

Q4: Why choose our company?

Professional manufacturer since 2000, provide various kinds of connectors and cable assembly. Small MOQ demand. High quality, competitive price with best service. Available for OEM/ODM order.

1.Verification reliability of raw materials

There is its own special laboratory for the selected raw materials for performance verification and quality monitoring, to ensure that each material on the line is qualified;

2. Reliability of the terminal / connector selection

After analyzing the main failure mode and failure form of terminals and connector, different devices with different use environments choose different types of connectors to adapt;

3. Design reliability of the electrical system.

According to the product use scenario through reasonable improvement, merge lines and components, differentiated to modular processing, to reduce the circuit, improve the reliability of the electrical system;

4. Design reliability of the processing process.

According to the product structure, use scenarios, characteristics requirements to design the best processing process, through the mold and tooling to ensure the product key dimensions and related requirements.

10 years professional wiring harness manufacturer

✥ Excellent Quality: We have strict quality control system and professional quality team.

✥ Customized Service: Accept small QTY & Support product assembling.

✥ After-sales service: Powerful after-sales service system, online throughout the year, perfectly answering series of after-sales customer sales questions

✥ Team Guarantee : Strong production team, R & D team, marketing team, strength guarantee.

✥ Prompt Delivery: Flexible production time helps on your urgent orders.

✥ Factory price: Own the factory, the professional design team, provides the best price

✥ 24 Hour service: Professional sales team, providing 24-hour emergency response.