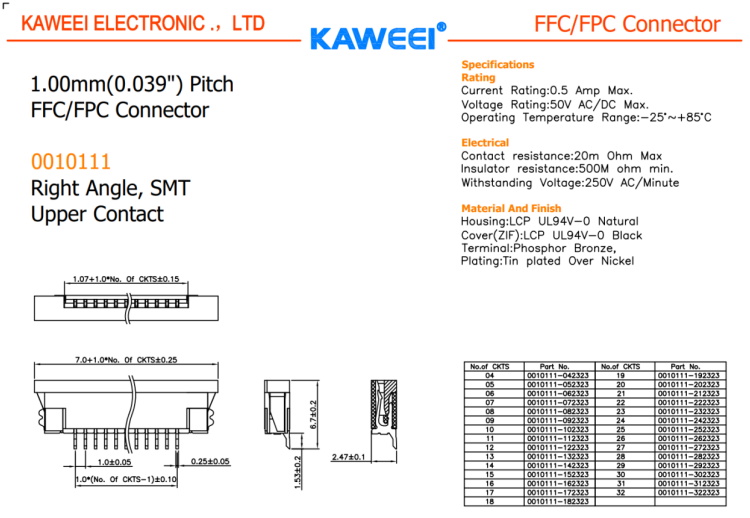

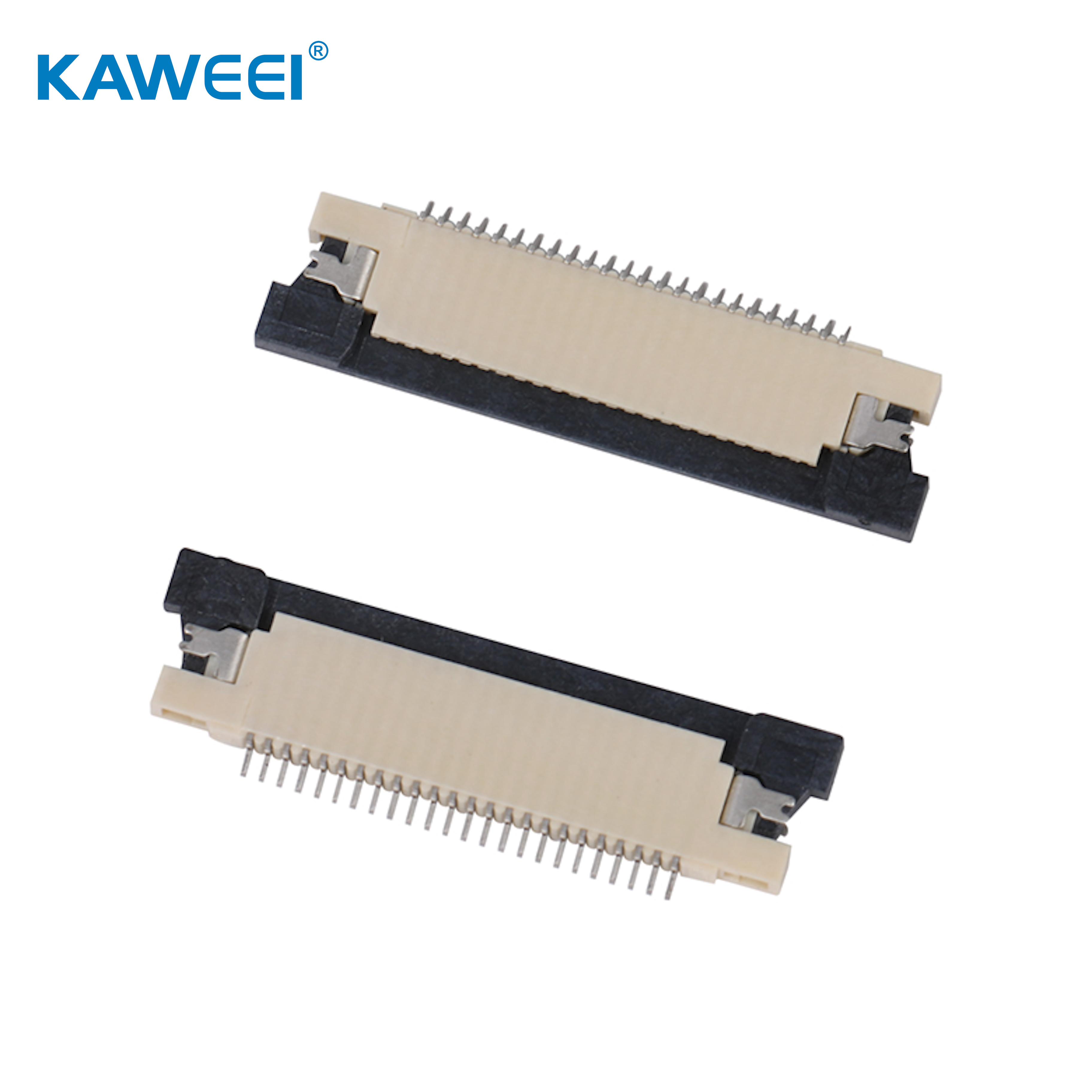

1.0mm Pitch FPC Top Upper contact right angle SMT Connector

Physical

| Product Name | 1.0mm Pitch FFC/FPC Connector |

| Color - Resin | Natural |

| Plating - Terminal | Phosphor Bronze |

| Material - Plating Mating | Tin,Matte Tin or Gold plating over Nickel |

| Material - Housing | LCP UL94V-0 Natural |

| Temperature Range - Operating | -25°C to +85°C |

Electrical

| Current - Maximum | 0.5 Amp |

| Voltage - Maximum | 50V AC/DC |

| Contact resistance: | 20m Ohm Max |

| Insulator resistance: | 500M ohm min. |

| Withstanding Voltage: | 250V AC/Minute |

Detail

| Product name | 1.0mm fpc Connectors |

| Certification | ISO9001, ROHS and the latest REACH |

| Handling Time(Lead time) | 1-2WKS (according to different products) |

| Sample | Mostly Free,Except the special items) |

| Minimum Order Quantity (MOQ) | 100PCS |

| Delivery Terms | EXW,FOB Shenzhen or FOB Hong Kong |

| Payment Terms | Paypal,T/T in advance. If the amount is more than 5000USD,we can do 30% deposit before production,70% before shipment. |

| Application: | Mobile phones、digital camera、MP3、MP4、Medical、Automotive and aerospace fields. |

| Service: | ODM/OEM |

Drawing

Product Tags

● FPC Connector

● Wire to Board Connector

● PCB board connector

● PCB connector

● FFC connector

● ZIP Connector

● Soldering connector

● FPC SMT Connector

● FFC Vertical connector

● Upper contact connector

● Top contact connector

1.Verification reliability of raw materials

There is its own special laboratory for the selected raw materials for performance verification and quality monitoring, to ensure that each material on the line is qualified;

2. Reliability of the terminal / connector selection

After analyzing the main failure mode and failure form of terminals and connector, different devices with different use environments choose different types of connectors to adapt;

3. Design reliability of the electrical system.

According to the product use scenario through reasonable improvement, merge lines and components, differentiated to modular processing, to reduce the circuit, improve the reliability of the electrical system;

4. Design reliability of the processing process.

According to the product structure, use scenarios, characteristics requirements to design the best processing process, through the mold and tooling to ensure the product key dimensions and related requirements.

10 years professional wiring harness manufacturer

✥ Excellent Quality: We have strict quality control system and professional quality team.

✥ Customized Service: Accept small QTY & Support product assembling.

✥ After-sales service: Powerful after-sales service system, online throughout the year, perfectly answering series of after-sales customer sales questions

✥ Team Guarantee : Strong production team, R & D team, marketing team, strength guarantee.

✥ Prompt Delivery: Flexible production time helps on your urgent orders.

✥ Factory price: Own the factory, the professional design team, provides the best price

✥ 24 Hour service: Professional sales team, providing 24-hour emergency response.